In the industrial sector, the demand for innovative solutions that combine efficiency and sustainability is continually growing. Electric boosters, in particular, are revolutionizing applications that require enhanced pressure of gases or fluids. In this context, Interfluid positions itself as a specialized partner capable of designing and customizing electric boosters to meet specific customer needs.

What are electric boosters?

Electric boosters are high-efficiency electric compressors designed to increase the pressure of compressed gases or liquids. These devices represent a significant advancement over traditional pneumatic solutions, offering precise control, a substantial reduction in operating costs, and a smaller environmental footprint thanks to energy savings.

Advantages of electric boosters

- energy savings: electric boosters, like the model offered by our partner HII Group, consume significantly less energy than conventional compressors;

- reduced maintenance: electric technology requires less maintenance compared to pneumatic solutions;

- precise control and reliability: they provide accurate control over operational variables, making them ideal for critical applications;

- versatility: widely used across various industries, including aerospace, automotive, chemical, and pharmaceutical sectors.

Application fields

- automotive industry: Increasing gas pressure in testing systems or assembly processes;

- chemical and pharmaceutical industries: maintaining constant pressure during production processes;

- aerospace: Compressors used in testing and the development of new materials;

- Testing of Components and Equipment: simulating extreme pressure conditions.

The unique value of Interfluid's electric boosters

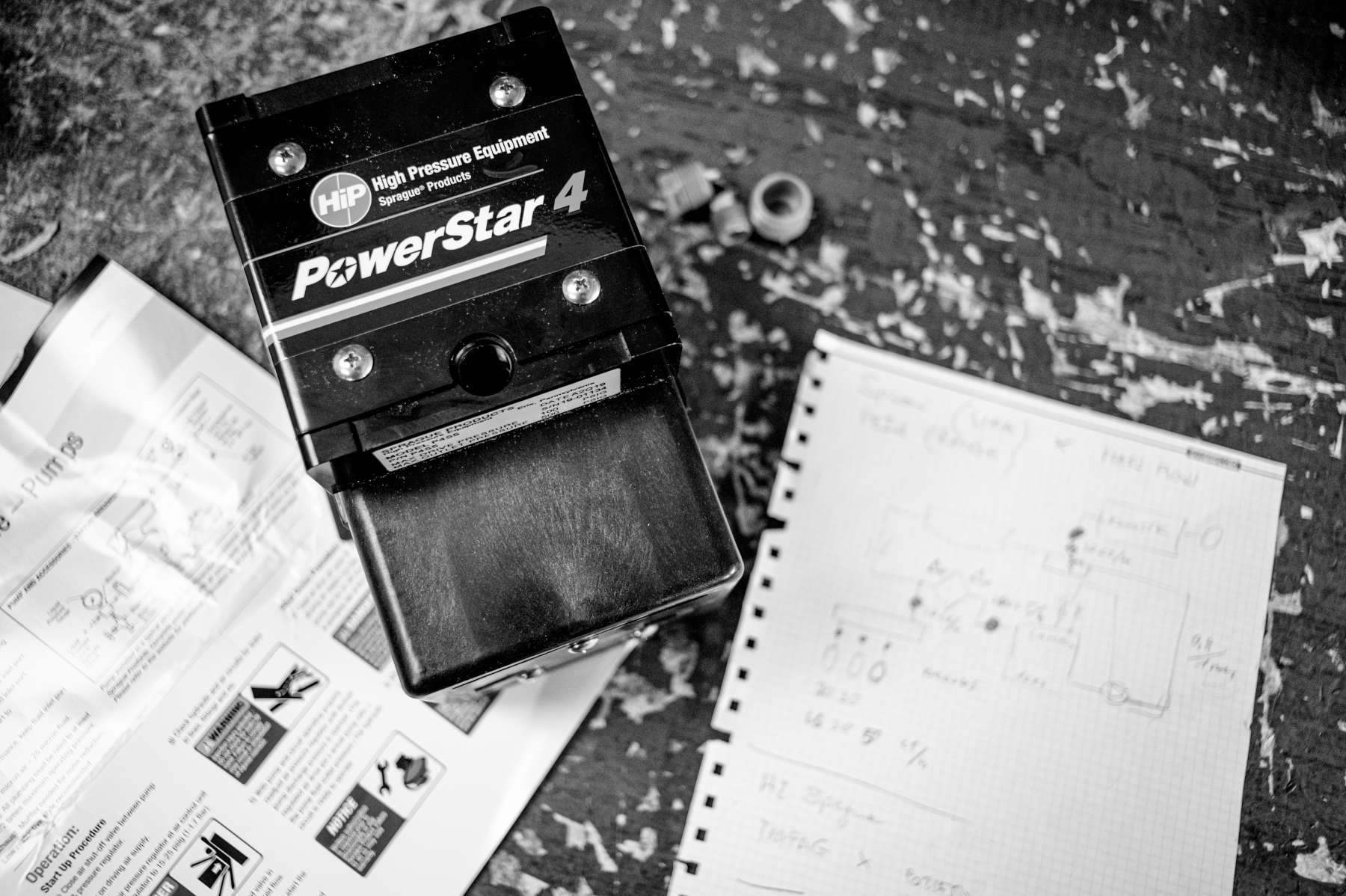

A practical example of electric booster usage can be seen in the high-pressure equipment testing sector. A leading industrial machinery manufacturer implemented an electric booster designed by Interfluid for their testing operations. The proposed solution enabled the client to reduce maintenance costs by 30%, increase operational efficiency, and enhance safety measures.

The unique value of Interfluid's electric boosters

One distinguishing feature of the electric boosters supplied by Interfluid is their ability to reduce energy consumption while optimizing efficiency. Furthermore, these systems can be sized and customized according to client needs, making Interfluid the ideal partner to ensure maximum performance in every application.

Technical data of electric boosters

The following table shows the most significant technical data of electric boosters:

|

Technical Feature

|

Value

|

|

Maximum Output Pressure

|

Up to 1000 bar

|

|

Maximum Flow

|

Up to 1,000 Nm³/h

|

|

Electric Power

|

5-50 kW

|

|

Pressure Regulation

|

Precisely adjustable via electronic control

|

|

Energy Efficiency

|

Up to 40% energy savings compared to traditional pneumatic compressors

|

|

Construction Materials

|

Stainless steel for parts in contact with gas

|

|

Gas Compatibility

|

Technical gases (nitrogen, argon, hydrogen) |

Why choose Interfluid for your electric booster

If your business requires a high-pressure system for critical industrial applications, electric boosters are the perfect solution.

With Interfluid, you benefit from customized solutions tailored to your specific needs. Whether your goal is to reduce energy costs, improve operational efficiency, or ensure safe and reliable performance, Interfluid is the partner you can rely on.

Feel free to contact us for a personalized consultation or to request more information about integrating electric boosters into your industrial operations.