Internal gear pumps: construction technology, operation and advantages

Pumps are most definitely the heart of any hydraulic circuit. Indeed, it is the pump that regulates the entire system's movement, the actuators, the cylinders, the motors. Choosing the correct hydraulic pump and selecting the most relevant parameters are therefore essential when designing a system. How do internal gear pumps work? Which are their benefits? In this article we tried to answer this questions.

The importance of a system’s pump is closely linked to the needs of the system. The more high performant a system needs to be, the more efficient the selected pump has to be. Internal gear pumps are considered to be some of the most efficient pumps to date. Let us see why.

What are the advantages of internal gear pumps?

The main feature of internal gear pumps is their design, which makes them quiet and highly performant:

- quick response to rpm variations applied.

- Elevated volumetric efficiency.

- Elevated pressure stability.

- Reduced flow rate pulsations.

- Conception of innovative solutions, thanks also to the new four-quadrant pumps or reversible pumps/motors and pumps specially designed for Servo applications.

A further indirect advantage of using internal gear pumps is that they require high filtration performance fluids, benefiting all other components, since clean fluid helps reduce wear over time.

Internal gear pumps applications

These characteristics have enabled internal gear pumps to be introduced in a multitude of applications of various natures. A selection of the applications that Interfluid's technicians have worked on are summarised below.

- In contexts where energy efficiency is of particular importance, internal gear pumps help reduce energy waste in accordance with system working pressures, ensuring flow rate and pressure stability. This is certainly the case with Bucher QX pumps and Hydraut HG pumps. The former originate from the historic QT Series and production has already reached the 5th generation of pumps. Bucher QX pumps are designed with robust components and feature "multistage pressure" that enables continuous working pressures up to 350 bar, with peaks of 400 bar. Hydraut HG internal gear pumps are perfectly interchangeable with Rexroth's PGH series, Eckerle's EIPC – EIPH series and Voith's IPV - IPH series.

-

In some cases, it may be necessary to bring engine revolutions as low as possible (even when the engine is stationary) to meet the need to reduce energy consumption or for applications that require a variable flow rate system. For this type of situation, Bucher has studied the QXEH range of internal gear pumps, deriving from the QX series but designed for servo applications. While working at lower pressures than Bucher's QX pumps (up to 250 bar with peaks at 280 bar), Bucher's QXEH pumps allow rapid variations in motor revolutions—typical of brushless motors—, with transient management function, pressure stopped pump or short reverse rotations for decompression.

-

With energy saving in mind, but in a situation opposite to that above, i.e., where the pump's cylinder capacity needs to be reduced in accordance with the necessary flow rate, while increasing the number of engine revolutions (typical of brushless motors), Bucher has designed the Bucher QXEHX pump, developed specifically for use with high-speed drives and resistant materials.

- QXEM pumps, which can also work as motors, have been developed for systems that need to be simplified. These pumps are also called four-quadrant pumps, and are able to drive the actuator directly, reverse its direction of rotation and, in certain cases, also recover energy from the system itself.

Internal gear pumps for special fluids

Internal gear pumps are often erroneously deemed to be delicate and expensive pumps. However, although the initial cost may be higher than for other applications, with the necessary technical adjustments, aimed at keeping the fluid in an efficient state, internal gear pumps are in actual fact able to provide indisputable advantages.

Considering their high volumetric output and low flow rate and pressure pulsations, combined with their rapid response to engine revolutions, internal gear pumps are well suited for dosing applications, enabling precise mixing and compatibility of materials in contact. This is the case with Bucher's QXP pumps, designed for applications with special fluids and use with polyols. Bucher even has a solution for low viscosity fluids, that is, its QXV internal gear pump, which is able to guarantee efficiency even in conditions where other pumps are unable to operate.

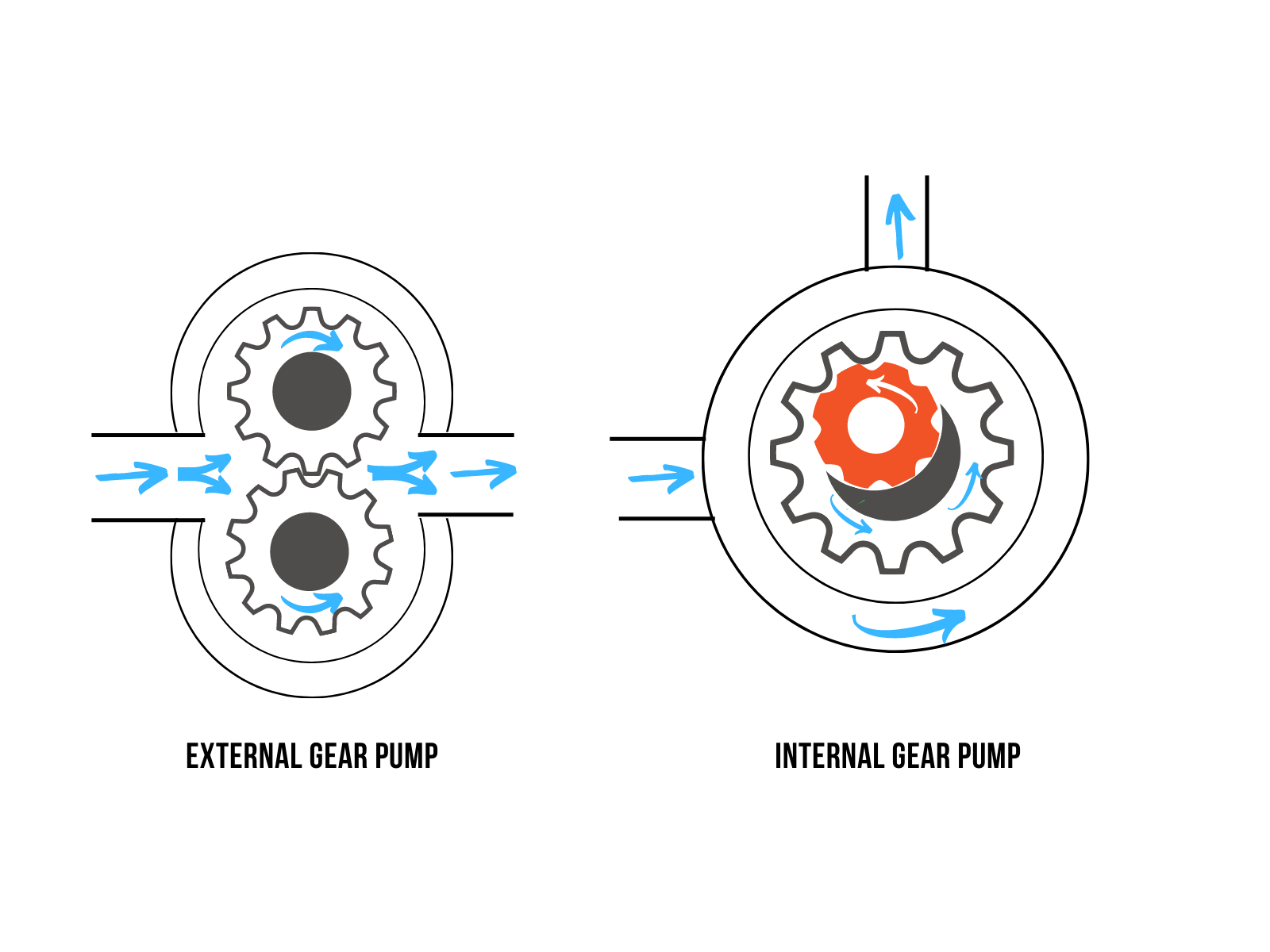

What's the difference between internal gear pumps and external gear pumps?

Although their name evokes similarity, there is a huge difference in how they are built and how they operate. Internal gear pumps are more complex, but essentially more efficient in transferring flow rates, guaranteeing higher operating pressures. External gear pumps, on the other hand, are based on less advanced technologies and, while effectively transferring the necessary flow rate, their use is limited to simple and less refined applications due to lower yields, elevated noise and the work pressures that can be used.

A type of pump that is potentially a valid alternative to internal gear pumps—including in terms of cost—, and that is somewhere between this technology and that of external gear pumps—with which it shares the same structure—, is Marzocchi's Elika elical gear pump that we discussed in the article published on our blog at this link.

Written with the collaboration of Gianluigi Pacelli, Technical Account Manager Interfluid

-1.jpg?noresize&width=600&height=450&name=ELIKA%20marzocchi%20pompe%20(2)-1.jpg)