The Pneumax 3000 EVO Series solenoid valves represent a highly technological and versatile solution for modern industrial automation. Designed to offer maximum operational efficiency and reliability, these solenoid valves can be successfully used in various sectors, meeting specific technical needs and ensuring high quality and performance standards.

Main technical characteristics of the 3000 EVO Series solenoid valves

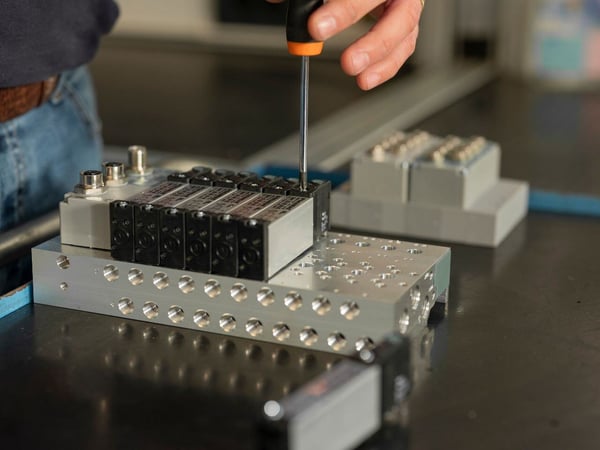

The 3000 EVO Series stands out for its extraordinary operational flexibility and extreme ease of configuration and is available in two versions, the 3100 version with compact dimensions of 10.5 mm and a flow rate of up to 200 Nl/min, and the 3400 version of 15.5 mm with a flow rate of up to 600 Nl/min.

These solenoid valves allow for quick valve replacements without the need to disconnect pneumatic connections, an advantage that significantly reduces maintenance times and optimizes overall plant productivity.

Among the features that make these solenoid valves particularly suitable for industrial contexts, we find:

- robust aluminum bodies with integrated electrical connections, perfect for demanding industrial environments;

- manual control for immediate and precise interventions during maintenance activities and operational tests;

- integrated LED that allows immediate monitoring of the operating status, thus facilitating the rapid identification of any anomalies;

- IP65 protection rating, ideal for ensuring safe and reliable operations even in the harshest environmental conditions.

Specific applications of the 3000 EVO Series solenoid valves

The 3000 EVO Series solenoid valves are designed to meet the specific needs of various industrial sectors, ensuring high and constant performance in very different operating contexts.

Industrial automation and robotics

Industrial robotics requires components capable of ensuring precision, speed, and reliability in movements, and the 3000 EVO Series, thanks to its compact design and structural lightness, represents an ideal solution for these systems. The valves allow precise and constant control of the pneumatic flow, essential for the precision of robotic operations, thus increasing overall performance and reducing the risk of errors.

Packaging sector

In the packaging sector, speed and reliability are fundamental criteria. The 3000 EVO Series solenoid valves are designed to work efficiently under different operating conditions, with positive pressures up to 10 bar and the ability to manage vacuum, characteristics that make them particularly suitable for high-speed packaging machines, ensuring production continuity and maximum operational safety.

Industrial assembly

Industrial assembly operations require components capable of adapting quickly to operational variations and configuration changes. The 3000 EVO Series solenoid valves offer effective and flexible management of both vacuum and positive pressures, making it possible to perform delicate and complex operations with absolute precision and safety.

Compatibility and integration with multiprotocol systems

The versatility of the EVO Series solenoid valves is further enhanced by the perfect integration with the Pneumax PX Series multiprotocol module, a technology that allows communication with standard market protocols such as CANopen®, PROFIBUS, EtherNet/IP, EtherCAT®, PROFINET IO RT, IO-Link and CC-Link IE. Thanks to this integration, the system guarantees effective and constant communication, reducing configuration times and improving overall plant management.

Advanced automation in industry 4.0

In line with the principles of Industry 4.0, the integration of the 3000 EVO Series solenoid valves allows the creation of intelligent and reactive automated systems, capable of operating autonomously and with high levels of safety. Through advanced functions such as predictive maintenance and continuous monitoring, it is also possible to significantly reduce machine downtime and optimize operating costs.

Investing in the 3000 EVO Series solenoid valves means choosing technological innovation, the reliability and flexibility necessary to successfully face the challenges of contemporary industrial automation.