What is a 4 quadrant operation and why choosing it

The collaboration with Bucher gave Interfluid the chance to test internal gear bidirectional pumps QXM and QXEM in some sectors, reaching up to 70% energy saving.

In this article we will examine the main characteristics of 4 quadrant variable speed systems, and we shall assess the contexts in which their use is recommended.

The search for new technological solutions is an essential leverage for any company wishing to remain highly competitive on their market. However, in view of the constant rise in industrial energy consumption, it has been necessary to shift the focus towards researching new ways to augment the efficiency of industrial machinery and to reduce their environmental impact. The data released at the end of 2020 had reported an encouraging drop in energy consumption owing to the global pandemic, but as early as the first quarter of 2021, with the restart of activities, an increase was registered in global energy consumption which once again sounded the alarm, especially considering the rise of energy costs expected by the end of this year.

Moreover, the need for new solutions to improve the efficiency of industrial machinery has become more urgent owing to the new mandatory legal requirement for energy diagnostics, which has led to an exponential rise in the number of requests for the development of energy saving solutions in industrial production, a task that is often passed on to the suppliers of automation components.

Thanks to an exchange with some of the principal producers of industrial machinery in strategic sectors and to the consolidated partnership with Bucher, Interfluid has had the opportunity of testing improvements in machine efficiency that are achievable thanks to the use of 4 quadrant control, with particular reference to the Bucher QXM and QXEM internal gear reciprocating pump.

What is a 4 quadrant operation

Variable speed hydraulic systems are generally characterized by a higher degree of complexity than traditional constant-speed systems and their main advantages actually consist in the possibility to save up to 70% in energy costs. In our study, we are going to analyse the main characteristics of 4 quadrant variable speed systems, and we shall assess the contexts in which their use is recommended.

A 4-quadrant pump has 3 outstanding technical characteristics:

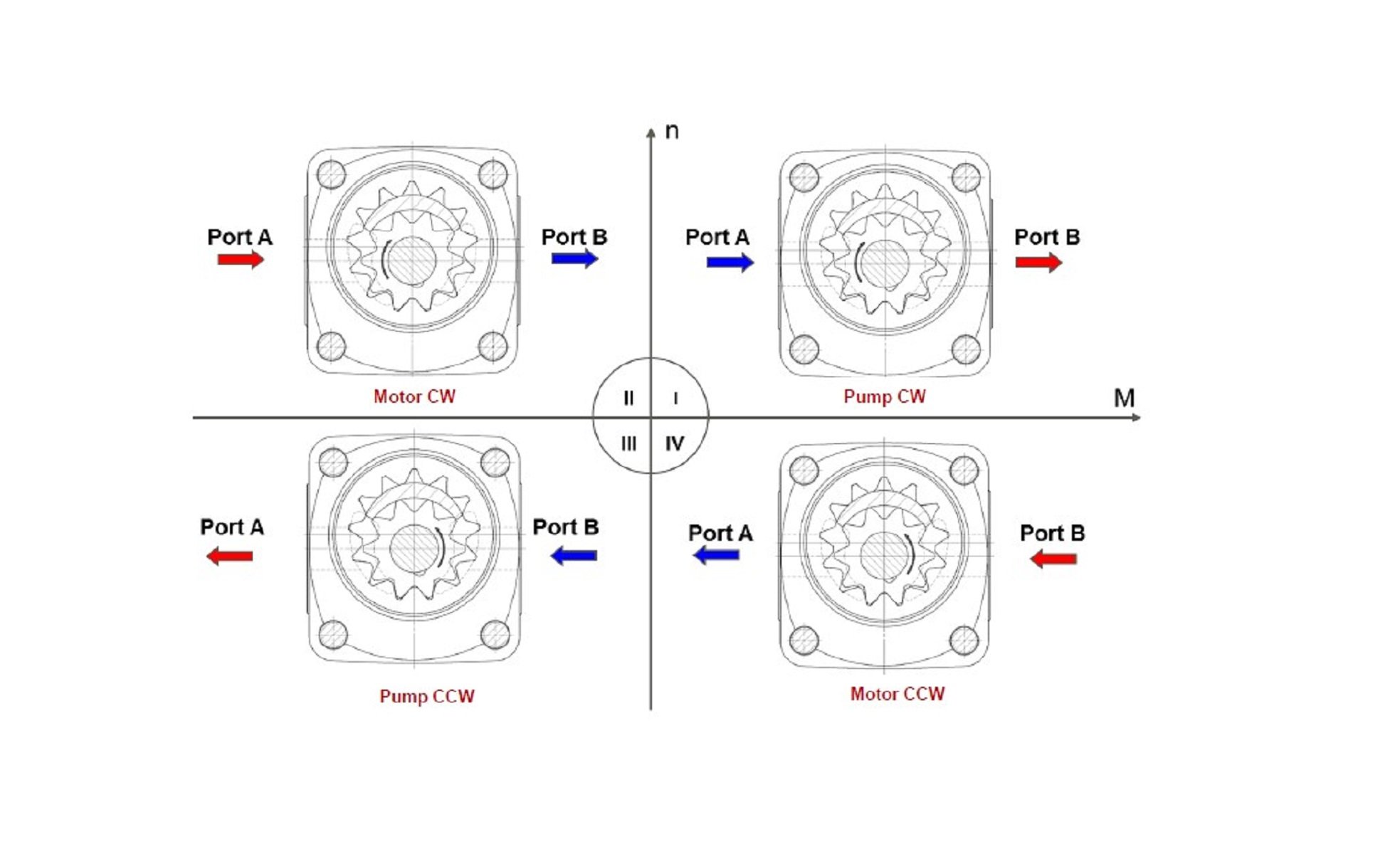

- it can operate as a pump and also as a motor;

- its rotational direction may vary;

- if used in an adequately structured system, it may work as a power generator.

In the quadrants in which the pump acts as a motor (quadrants 2 and 4) the speed and the torque have the same direction (both positive or both negative) while in the quadrants in which it acts as a pump (quadrants 1 and 3), speed and torque have opposite directions (one negative and one positive). Reciprocating pumps are suitable for applications in both clockwise and anti-clockwise rotation, thanks to the possibility to change the rotational direction, when either functioning as a pump or as a motor.

Benefits of 4 quadrant technology

If used on an adequately organized system, four quadrant technology enables:

A saving of energy costs.

In a servo system in which a reciprocating internal gear pump is combined with an inverter and brushless synchronous motor, it is possible to recover electrical or oil hydraulic energy:

- electrical energy thanks to the regenerative braking of the brushless motor, when the pump operates as a motor, the motor tor que is opposite to the direction of rotation and kinetic energy is generated which can be reutilised (this function is known as regenerative braking or KERS, Kinetic Energy Recovery System) either by accumulation in batteries (as in the case of hybrid cars) or by returning it to the grid for machinery or electric operations, or by storing it in system batteries aimed at supporting energy self-sufficiency.

- In applications with differential displacement, with the use of hydraulic accumulators, the difference in volume is accumulated and then converted into hydraulic energy, which may be returned to the system. In both cases, the use of a brushless motor also guarantees a rapid and high-precision start-up.

Plant simplification.

A 4-quadrant system is also recommended in environments in which it is possible and necessary to simplify the plant, thanks to the elimination of flow control valves. Thanks to reverse rotation, the pump-motor may decide the oil flow direction and pilot an actuator without the use of a flow control valve. Furthermore, this allows for a reduction in the number of components needed to build the plant and, according to the complexity of the system, spare parts and oil consumption may also be reduced.

Applications of 4 quadrant technology

The possibility to control speed and torque in both directions makes four quadrant technology particularly suitable for applications requiring multi-quadrant variable speed operations.

4 quadrant pumps are also ideal in systems requiring a dynamic response, reliability and repetitiveness.

Of the principal applications, Interfluid has had the opportunity to verify the advantages of 4 quadrant technology applied to:

- vertical presses,

- bending presses,

- presses for plastic and rubber,

- presses for glass,

- broaching machines,

but these are just a few of the application fields of the 4 quadrant operation, we are thus developing new solutions in many other fields.

How to understand whether 4 quadrant technology is suitable for your application

-

As mentioned in the previous paragraphs, not all applications lend themselves to the use of four quadrant pumps; on the contrary, there are some cases in which this technology is not recommended, or its application may not be possible. Interfluid technicians analyse the production context by assessing a series of parameters, comprising:

- Type of shaft: 4 quadrant technology is not suited to multi-shaft applications, but only those with a single shaft. 4 quadrant pumps perform well in applications requiring synchronism, in which 2 shafts operate in alignment, as in bending and vertical presses.

- Type of machine cycle: required pressure and flow rate, overload.

- Investment analysis: the solution presented will be based on real plant requirements and, following an analysis of the technological investment, will consider the implementation costs and the reduced amortization period compared to alternative solutions.

- Type of shaft: 4 quadrant technology is not suited to multi-shaft applications, but only those with a single shaft. 4 quadrant pumps perform well in applications requiring synchronism, in which 2 shafts operate in alignment, as in bending and vertical presses.

Interfluid distributes Bucher internal gear pumps, known for their high reliability, including QXM and QXEM internal gear bidirectional pumps.

-1.jpg?noresize&width=600&height=450&name=ELIKA%20marzocchi%20pompe%20(2)-1.jpg)