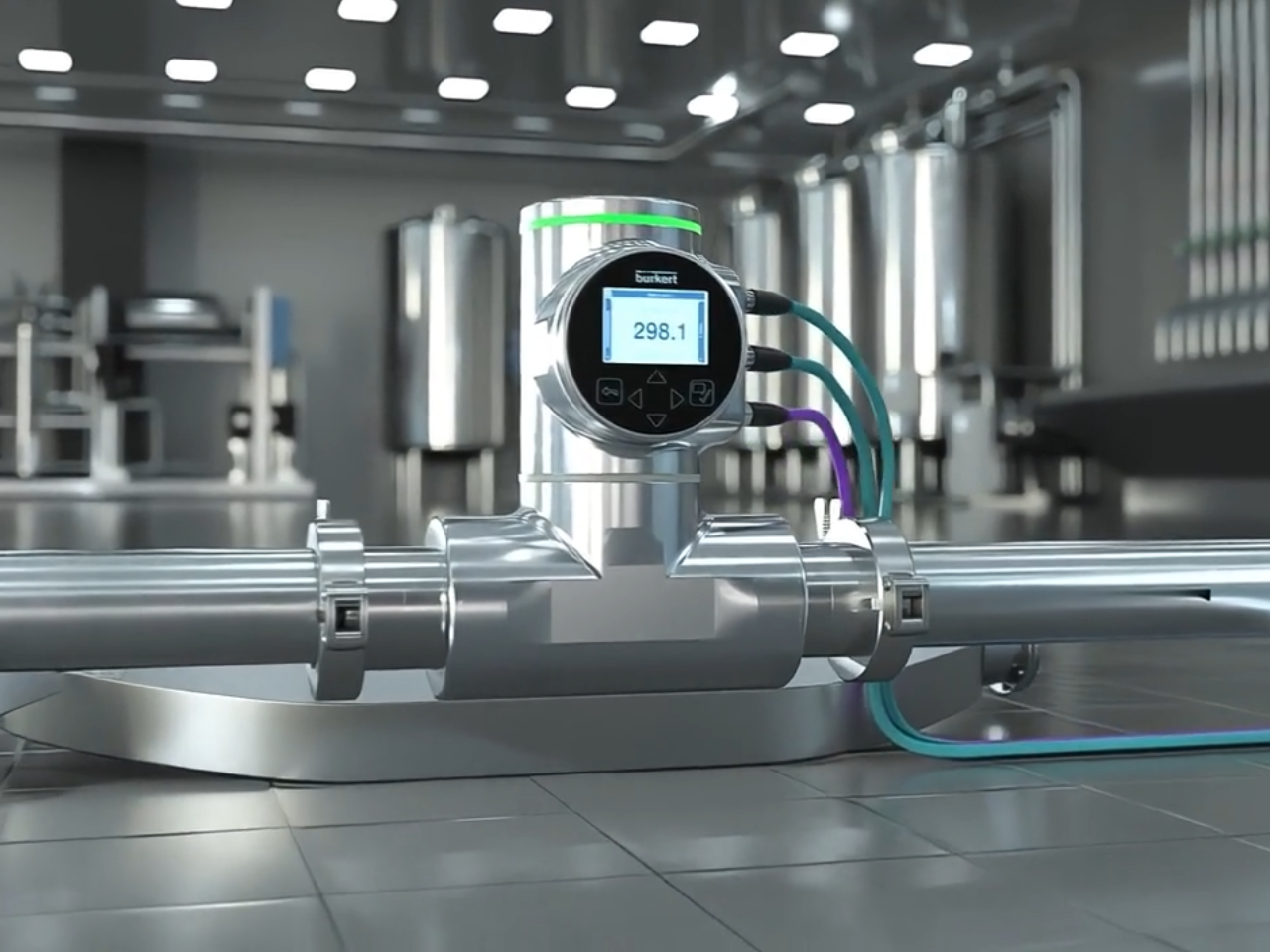

FLOWave type 8098 flowmeter by Bürkert: precision and hygiene

In the industrial world, accurate flow measurement of fluids is essential to ensure the quality and safety of the final product. The FLOWave type 8098 flowmeter by Bürkert represents a cutting-edge solution to meet these needs, thanks to the innovative SAW (Surface Acoustic Waves) technology, which enables precise and reliable measurements without internal parts coming into direct contact with the fluid.

SAW technology: non-contact measurement

FLOWave 8098 uses patented technology based on surface acoustic waves, which eliminates the presence of internal sensors. This innovative method ensures extremely accurate volumetric and mass flow measurement, avoiding common issues such as pressure drop, material incompatibility, dead zones, and internal component maintenance.

With a measurement error of less than 0.4%, this device is ideal for highly regulated sectors such as food, pharmaceutical, and biotechnology industries, where measurement quality is crucial to process safety and effectiveness. SAW technology also allows the accurate detection of air bubbles and particles in the fluid, further enhancing control quality.

Hygienic design and regulatory compliance

One of the most appreciated features of the FLOWave 8098 is its "hygienic design": made entirely of 316L stainless steel and without internal elements that could contaminate the fluid, the device complies with the highest standards such as 3-A, EHEDG, FDA, USP Class VI, and ASME BPE. It is therefore perfect for applications where hygiene is essential, such as pharmaceutical and food production.

Its extremely smooth internal surface and absence of dead zones, combined with a self-draining design, greatly simplify and speed up CIP/SIP cleaning and sterilization processes, reducing operational time and costs and enabling faster, more efficient production cycles.

Digital communication and Industry 4.0 integration

FLOWave type 8098 offers integrated digital communication with certified protocols such as PROFINET, EtherNet/IP and IO-Link, allowing for fast and simple integration into modern digital infrastructures. This feature makes the device an essential component of Industry 4.0, enabling real-time performance monitoring, early anomaly detection, and predictive maintenance strategies.

Thanks to its ability to seamlessly integrate into advanced automation systems, FLOWave 8098 ensures maximum process transparency, increasing overall plant efficiency and significantly reducing downtime and associated costs.

Flexibility and easy installation

Weighing less than 10 kg and featuring extremely compact dimensions, the FLOWave 8098 flowmeter is designed to be easily transported and installed even in tight spaces. It offers flexibility in installation positioning and the ability to configure the transmitter based on specific customer needs, allowing optimal adaptation to any type of application.

This ease of installation and maintenance makes the flowmeter an ideal solution not only for new installations but also for retrofitting existing systems—providing an optimal option for those needing to minimize integration time and costs.

Practical applications and operational benefits

Using FLOWave 8098 in various industrial sectors has shown clear advantages in terms of productivity and cost reduction:

- Pharmaceutical industry: Used in the production of infusion solutions, FLOWave 8098 allows extremely precise control of CIP (Cleaning in Place) and SIP (Sterilization in Place) flows, enabling timely detection of process parameter variations, avoiding product losses, and ensuring consistent quality over time. The accuracy in volume and density measurement also contributes to a significant reduction in waste.

- Food&Beverage industry: For example, in breweries, FLOWave 8098 monitors and optimizes the dosing of liquid ingredients, improving the consistency and final product quality. Its advanced fluid change detection system allows for a quick and effective transition from one product to another, preventing cross-contamination and minimizing waste.

- Biotechnology: FLOWave 8098 fully meets the strict requirements of the biotech sector, ensuring precise mass flow and density measurements even for fluids with specific characteristics. The absence of moving internal parts and the ability to detect bubbles and particles make the device ideal for maintaining high hygiene standards and preventing contamination that could compromise entire production batches.

Reduced operating costs and minimal maintenance

The complete absence of internal mechanical elements eliminates the need for periodic maintenance and replacement of worn components, drastically reducing operating costs. The robustness and reliability of FLOWave 8098 ensure exceptional operational continuity, contributing to efficient resource management and a significant return on investment.

FLOWave 8098: a strategic choice for quality processes

The advanced technology of the FLOWave 8098 flowmeter, its hygienic design, and digital integration make it an ideal solution for those seeking high performance, reliability, and process optimization.

In an industrial context increasingly focused on efficiency and quality, tools like the FLOWave 8098 are essential not only to improve production processes but also to ensure safety and regulatory compliance, representing a strategic choice to successfully meet daily operational challenges.