Kick and Drop Solenoid Valves: How to Save 80% Energy in Industrial Applications

In today’s industrial landscape, where energy efficiency and environmental sustainability have become essential priorities, Bürkert's Kick and Drop solenoid valve technology represents a revolutionary innovation. This cutting-edge technology not only optimizes industrial processes but also ensures a drastic reduction in energy consumption, making it the ideal solution for forward-looking companies.

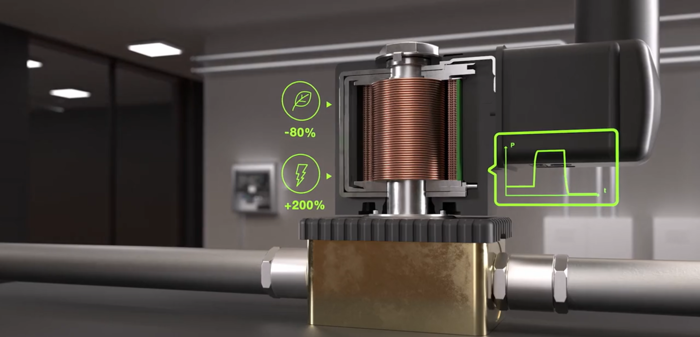

The Technological Core: How the Kick and Drop System Works

Kick and Drop technology marks a true revolution in the field of solenoid valves, introducing an innovative approach to energy management and fluid control. This intelligent system combines high performance and energy efficiency in an unprecedented way, thanks to a design that addresses the real operational needs of modern industrial applications.

A Dual Coil for Maximum Efficiency

The Kick and Drop system is based on an innovative principle using a double winding coil. Unlike traditional solenoid valves, this technology operates in two distinct phases:

- Opening phase: An initial high current pulse overexcites the coil, generating the pulling force necessary to open the valve;

- Holding phase: After approximately 500 milliseconds, the system automatically switches to a low-energy holding operation.

The real breakthrough, however, lies in the integration of electronics directly within the coil, eliminating the need for external control units and significantly simplifying installation and maintenance.

Tangible Benefits for Companies

Implementing Kick and Drop technology in solenoid valves offers a series of tangible benefits that go far beyond simple energy savings. These advantages translate into significant improvements across various operational areas, from energy efficiency to workplace safety, maintenance, and space management.

Extraordinary Energy Savings

Solenoid valves with Kick and Drop technology represent a decisive leap in industrial energy efficiency, offering up to 80% energy savings compared to traditional solutions. This substantial saving translates into multiple tangible benefits:

- Significant reduction in operating costs: Lower energy consumption directly impacts company energy bills, with savings that can amount to thousands of euros annually per plant;

- Lower environmental impact: The drastic reduction in energy consumption results in a significant decrease in CO₂ emissions, contributing to corporate sustainability goals and compliance with increasingly stringent environmental regulations;

- Rapid return on investment: Thanks to exceptional energy savings, the investment cost is amortized relatively quickly, typically within 2-3 years of installation.

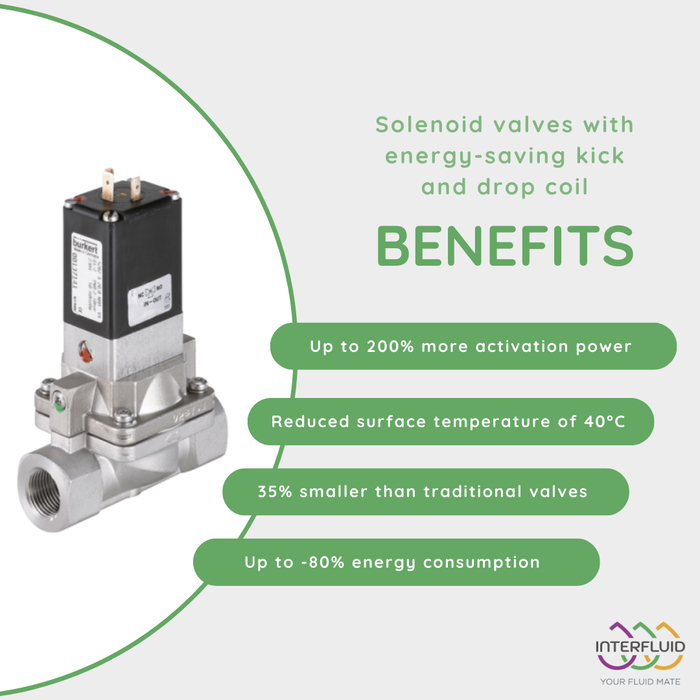

Superior Performance

As noted, the benefits of Kick and Drop technology extend beyond energy savings to a range of performance advantages that make it a cutting-edge 360° solution:

- Switching pressure up to 200% higher: This increase allows greater operational flexibility and the ability to handle more demanding applications with the same valve;

- Reduced surface temperature from 92°C to just 52°C: The significant reduction in operating temperature enhances workplace safety and reduces the risk of accidental burns;

- Reduced self-heating: This significant drop in operating temperature translates into longer component life and reduced maintenance needs;

- Compact design with up to 35% space savings: Optimized sizing allows greater installation flexibility and reduces control panel bulk.

Improved Work Environment

A key aspect of Kick and Drop technology is its positive impact on the work environment, particularly in terms of noise pollution:

- Complete elimination of buzzing and whistling: Unlike traditional or PWM technology valves, Kick and Drop valves operate in total silence, eliminating annoying switching noises;

- More comfortable work environment: The absence of noise contributes to a more pleasant and less stressful workplace for operators;

- Greater comfort for operators and animals: The quiet operation is especially appreciated in sensitive environments such as hospitals, laboratories, or facilities that house animals.

Practical Applications and Versatility

The true strength of Kick and Drop technology lies in the versatility of its applications. Thanks to its unique features, this solution is perfectly suited to a wide range of industrial sectors and operational scenarios, offering its distinctive benefits in each context. Its ability to meet diverse needs makes it an ideal choice for multiple applications.

Application Sectors

The versatility of Kick and Drop technology makes it suitable for a wide range of industrial applications, including:

- Hydraulic sector: Ideal for water control systems, treatment plants, and distribution networks where reliability and energy efficiency are crucial;

- Heating technologies: Perfect for HVAC systems and thermal applications where precise control and energy savings are essential;

- Gas and water safety systems: The technology ensures reliable and safe operation in critical safety applications;

- Environments with stringent EMC requirements: Full EMC compliance makes these valves ideal for environments sensitive to electromagnetic interference;

- Systems with high-lime water: The reduced operating temperature minimizes calcification issues, increasing system longevity.

Operational Flexibility

Kick and Drop technology stands out for its exceptional operational versatility, manifesting in several aspects:

- Universal operation (AC/DC, 50/60 Hz): The ability to operate with various electrical supplies simplifies inventory management and increases installation flexibility;

- Global use without adaptations: Compatibility with international standards allows the valves to be used anywhere in the world without modification;

- Easy integration into existing systems: The plug-and-play design facilitates the upgrade of existing plants, minimizing downtime.

Sustainability and the Future

At a time when environmental sustainability and energy efficiency have become indispensable priorities for the industrial sector, Kick and Drop technology presents a concrete response to future challenges. This is not only an advanced technological solution but also a real investment in sustainability and responsible innovation.

Environmental Impact

The adoption of Kick and Drop technology significantly reduces environmental impact:

- Lower energy consumption

- Reduction in CO₂ emissions

- Longer component life

- Reduced maintenance needs

Investment for the Future

The choice to implement solenoid valves with Kick and Drop technology represents a strategic investment that:

- Anticipates future energy-saving regulations

- Improves operational efficiency

- Increases corporate competitiveness

A Winning Choice

Opting for solenoid valves with Kick and Drop technology is not just a technological choice; it is a strategic decision for companies looking toward the future. With its benefits in terms of energy savings, performance, and sustainability, this technology is an essential solution for modern industry.