-1.jpg?width=700&height=525&name=ELIKA%20marzocchi%20pompe%20(2)-1.jpg)

How to reduce noise in the workplace with helical gear pump Elika

Today’s hydraulic technology enables a considerable reduction of noise levels in the workplace. Internal gear pumps are particularly well-known for their low noise emissions. A more recent and very effective solution is provided by Marzocchi with their Elika helical gear pump.

When addressing the issue of health safety in the workplace, one of the topics that emerges most frequently is that of acoustic quality. Some industries are particularly noisy, because of the high level of pulsations in the industrial machinery employed, which exposes workers to dangerous decibel levels over the years.

It is no coincidence that the legislation regulating noise in the workplace is of an extensive and complex nature. According to article 190 of Italian Legislative Decree 81/08, all public and private companies with at least one worker must assess the noise levels on their premises. The UNI 9432:201 standards, a revision of the UNI 9432:2008 and UNI EN ISO 9612 standards, are furthermore aimed at assessing the levels of daily, weekly, and peak exposure, which may be utilized to fulfil the obligations laid down by the Legislation in force. We have mentioned just a few examples of a general nature, but there are numerous specific directives regulating noise in various industries.

Low noise hydraulic pumps: internal gear pumps and helical gear pumps

How can hydraulic technology contribute to reducing noise emissions in the workplace?

In recent years, hydraulic technology has evolved by developing innovative solutions such as servo pumps, with the primary aim of cutting energy consumption, but also to reduce environmental noise and, consequently, to improve the operators’ working conditions. If we take a closer look at the components, one of the solutions most frequently associated with low noise, is represented by internal gear pumps which allow for a significant reduction of noise emission levels thanks to particular construction features and an effective balancing of forces.

An alternative yet lesser-known solution among hydraulic pumps is provided by helical gear pump technology, such as Elika by Marzocchi whose main features are:

- low noise,

- low pulsation,

- high efficiency.

The shape of the Elika-patented tooth is the main characteristic enabling this pump to operate at a reduced noise level. The tooth profile without encapsulation (the principal source of noise in traditional gear pumps) allows not only a reduction in pressure oscillations but also the vibrations transmitted to other components connected to the pump (valves, tanks, and hoses) thus reducing noise emissions by an average of 15dBA compared to traditional external gear pumps.

How Elika helical gear pump works

The Elika series comprises pumps in the displacement range of 2.1 to 200 cm3/rev, which are perfectly interchangeable with the ALP2 and GHP2 Marzocchi gear pumps series. Maximum operating pressures are similar to those of the GHP Marzocchi series, i.e. up to 300 bar.

The helical teeth guarantee continuity of motion despite their reduced number. In addition, this feature considerably reduces the fundamental frequencies of pump noise and makes the resulting sound less impacting for the operator. The special shape of the Elika profile, patented by Marzocchi Pompe, bypasses the encapsulation typically associated with normal gear pumps, thus eliminating the main cause of noise and vibrations.

The helical teeth guarantee continuity of motion despite their reduced number. In addition, this feature considerably reduces the fundamental frequencies of pump noise and makes the resulting sound less impacting for the operator. The special shape of the Elika profile, patented by Marzocchi Pompe, bypasses the encapsulation typically associated with normal gear pumps, thus eliminating the main cause of noise and vibrations.

An axial compensation system integrated in the pump cover balances the axial forces induced by helical teeth in all operating conditions. This characteristic makes Elika pumps suitable for low speed and high-pressure operating conditions, with the consequent elimination of internal leakage, laminating from outlet to inlet and overheating of pump components.

Compared to other types of volumetric pumps on the market, Elika has a wider scope of application, in terms of rotational speed, working pressure range and viscosity bands.

When is the use of a helical gear pump recommended?

Owing to the aforementioned technical characteristics, Elika pumps are particularly well suited to applications in which low noise is a priority, as in the case of waste collection vehicles operating at night in cities, or for driving mechanisms in niche sectors such as luxury yachts.

Helical gear pumps are a relatively recent technology which, according to the application, may perform the same functions as vane pumps, a technology that is still in use but which, in certain contexts, may prove to be outdated. In such cases, the advantages of Elika mainly consist in lower noise and reduced pulsations.

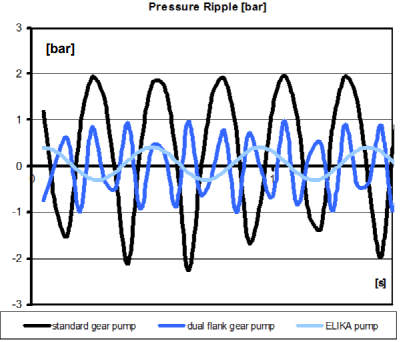

|

Pressure pulsation comparison between: external gear pump, dual flank gear pump, ELIKA pump. Regime 200 bar, 1500 rev/minute. |

Experience acquired with clients has enabled Interfluid to draw comparisons between the performances of internal gear pumps and Elika.

When studying the requirements of specific industries, such as those of luxury yachts or automatic AGV trollies, we have had the opportunity to test Elika pumps, which have proved to be a valid alternative in terms of noise reduction, even more effective in some cases than internal gear pumps, but at a lower cost.

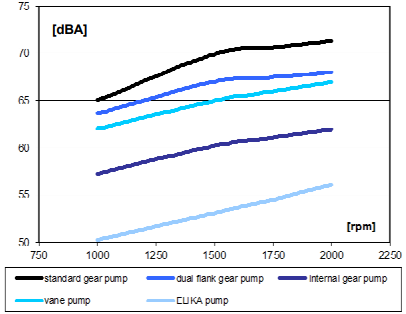

|

Noise comparison between: external gear pump, dual flank gear pump, internal gear pump, vane pump, Elika gear pump, pressure 200 bar. |

Based on the experience of Interfluid, Elika offers an alternative to internal gear pumps also in servo applications and is an excellent solution for producers of hydraulic control units intent on achieving a conspicuous reduction in the overall noise of their systems.