Pressure regulators: how they work, where they are used and why they are essential

At the heart of every industrial plant, from analytical laboratories to large-scale production lines, there is one variable that cannot be left to chance: pressure. An unstable value means uncertain results, safety risks, higher energy consumption and unexpected maintenance costs.

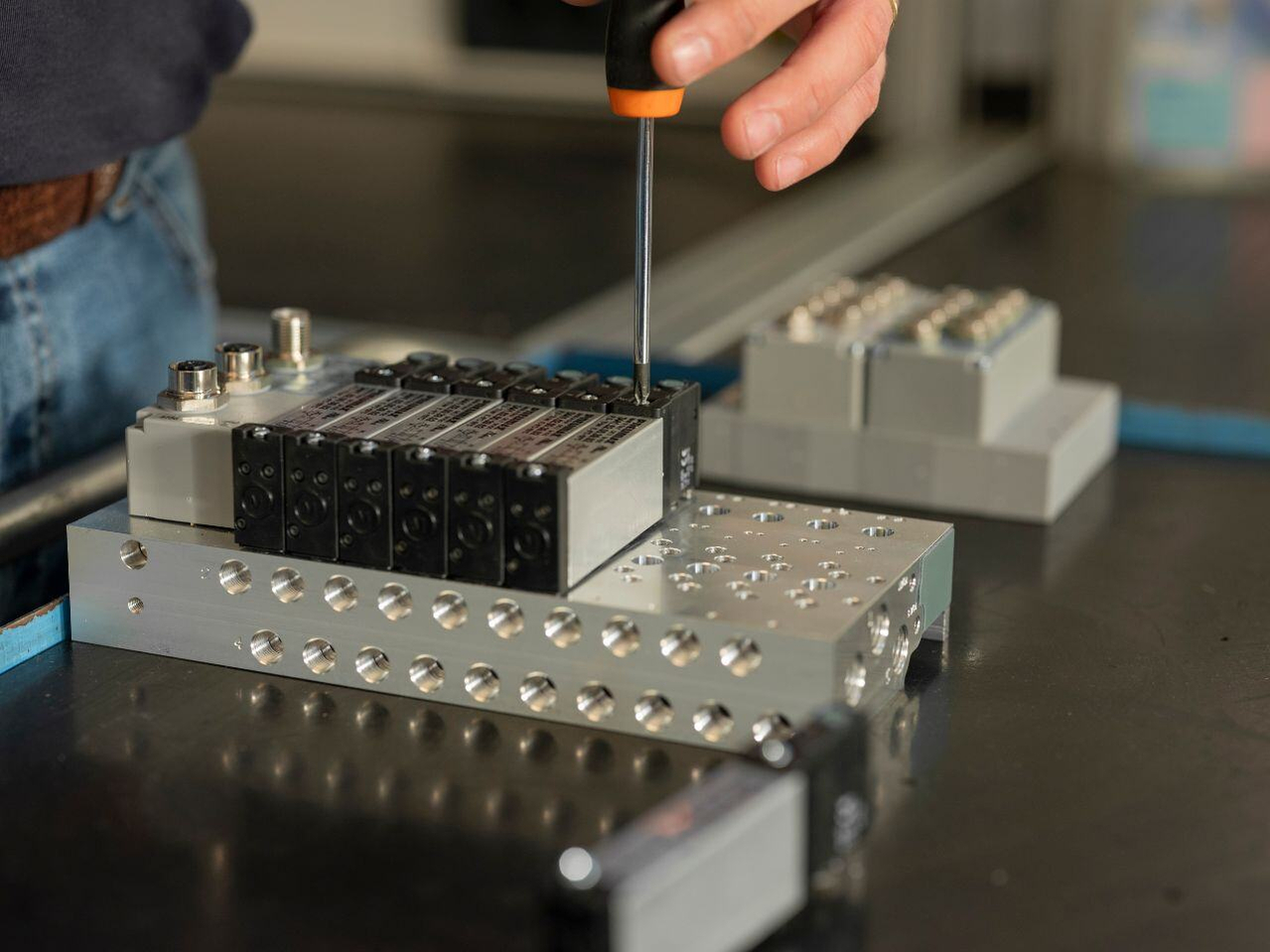

Pressure regulators are designed to prevent all of this: small components, but with a huge impact on process stability and reliability.

What is a pressure regulator and how it works

A pressure regulator is a device designed to keep the pressure of a fluid constant, whether gas or liquid, regardless of upstream pressure or flow variations. There are two main categories:

- Pressure reducing regulators: reduce and stabilize downstream pressure, making it suitable for the user

- Backpressure regulators: keep upstream pressure constant, releasing or recirculating fluid only when the setpoint is exceeded

The operating principle is simple but effective: a loading element (spring or pilot pressure), a sensing element (diaphragm or piston) and a control element (valve seat) work in balance to open or close the fluid passage depending on actual conditions.

Main types of regulators

Regulator technology adapts to different industrial needs:

- Spring-loaded regulators: compact, cost-effective and easy to use, they are the most common solution

- Dome-loaded regulators: use a pilot gas for extremely precise control and also allow remote adjustment

- Hybrid or air-loaded regulators: combine the advantages of both solutions, with applications in critical contexts such as reactors, autoclaves or high-pressure systems

Another distinction concerns the number of stages: single-stage regulators are sufficient in many applications, while dual-stage regulators ensure even more stable pressure, ideal in sectors where even small deviations can compromise quality and safety.

Fields of application: where pressure regulators make the difference

The use of pressure regulators is not limited to a few industrial niches but spans a wide variety of sectors, from large energy plants to research laboratories. Their versatility lies in the ability to adapt to very different fluids and operating conditions: high-purity gases, corrosive liquids, high flow rates, or systems where even a few millibars of deviation can compromise an entire process.

In every context, regulators help ensure operational continuity, result quality and operator safety. The choice of the most suitable model therefore varies according to the sector, the type of fluid and the pressure to be kept constant.

Here are some significant examples of application:

Oil & Gas and energy distribution

In oil and gas separators, compressor stations and pipelines, regulators keep pressure within safe values, preventing pressure surges and improving separation efficiency. In urban natural gas distribution networks, they are essential to reduce pressure to values compatible with domestic and industrial use.

Chemical and pharmaceutical industry

In reactors, autoclaves and fermenters, pressure stability directly affects reaction yield and operator safety. A backpressure regulator placed on the reactor discharge keeps the system pressurized in a controlled way, preventing oscillations that could alter the process.

Laboratories and scientific research

In gas chromatography systems, test benches and calibration units, even minimal variations can alter results. Dual-stage regulators and materials compatible with ultra-pure gases ensure repeatability and analytical accuracy.

Energy and power generation

From steam circuits in power plants to cogeneration systems, regulators keep pressure constant while protecting turbines and boilers. In nuclear plants or high-performance power stations, they are used to control cooling gases such as helium and nitrogen.

Hydrogen and alternative fuels

With the growth of H₂ infrastructure and fuel cell vehicles, regulators are indispensable both on board vehicles and in refueling stations. They keep the lines under controlled pressure, ensuring the safety of operators and users.

Cryogenic and industrial gases

In storage and transfer systems for oxygen, liquid nitrogen or LNG, regulators enable controlled venting and recirculation, preventing unwanted pressure build-ups and preserving the integrity of tanks.

High-pressure hydraulics and waterjet

In systems with fixed-displacement pumps, the regulator bypasses excess flow, preventing damaging pressure peaks. In waterjet cutting, where pressures can reach 100,000 psi (6,895 bar), a reliable regulator protects pumps and pipelines, ensuring continuous operation.

Special applications

From subsea systems for professional diving to hyperbaric chambers and life-support systems, regulators control breathing gases and maintain safe conditions in extreme environments.

Advantages for safety and efficiency

Integrating a pressure regulator into a system is not just about meeting technical specifications: it means achieving tangible benefits that impact safety, process quality and energy efficiency. A well-selected regulator becomes a true “enabler” of stable performance, reduces hidden costs related to waste and unplanned downtime, and helps extend the useful life of equipment.

Its role is therefore cross-cutting: it protects systems from extreme conditions, improves production consistency and helps companies keep consumption and maintenance under control.

Among the main advantages we can mention:

- Greater operational safety: the regulator prevents overpressure and unstable conditions, protecting operators and equipment. It does not replace a certified safety valve but works in synergy with it for continuous and precise control

- Process stability and product quality: constant pressure means controlled reactions, products compliant with standards and reduced waste. In sectors such as pharmaceuticals, this is an essential requirement

- Energy efficiency: reducing working pressure to the minimum necessary helps lower consumption. In compressed air systems, for example, reducing pressure by just a few bars can translate into significant energy savings

- Reduced maintenance costs: by limiting mechanical stress and pressure surges, regulators extend the service life of pumps, pipelines and downstream components. In addition, the ability to monitor their performance (e.g. creep and leak test) supports predictive maintenance strategies

- Uninterrupted productivity: a stable and safe system means fewer unexpected shutdowns and more continuous operation, with direct benefits for profitability

Integration with other high-pressure components

Regulators do not operate in isolation: they are an integral part of a system that also includes valves, pipelines, fittings, filters and certified measuring instruments.

In complex applications such as high-pressure test benches, waterjet systems or hydrogen refueling stations, regulators ensure that every component operates within its design limits, preserving the reliability of the entire system.

Their proper selection, combined with adequate upstream filtration and certified safety devices, is the basis for building systems that combine high performance with regulatory compliance.

Towards more reliable and efficient systems

Whether it is a matter of controlling just a few bar in a laboratory or thousands in a waterjet system, pressure regulators are an essential element for every industrial sector.

Their ability to combine safety, efficiency and quality makes them a strategic investment, not just a simple component.

In a context where energy, production continuity and risk reduction are top priorities, choosing the right regulator means giving solidity to the present and reliability to the future of industrial systems.