Hydro+Power test bench with Hydraut servopump: Industry 5.0 efficiency

When quality becomes a business strategy, technology must also rise to the occasion.

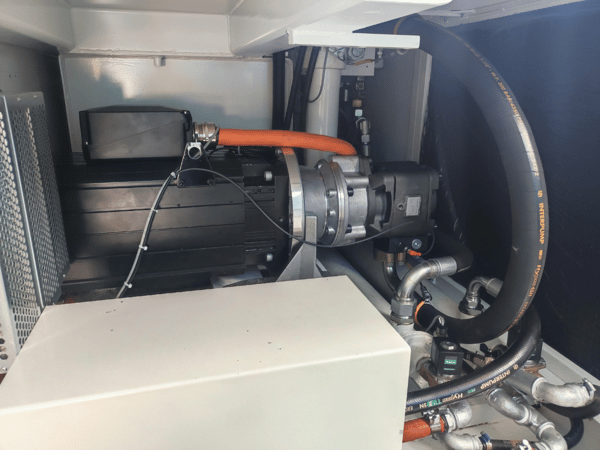

This vision led to the new impulse test bench up to 300 bar created by Hydro+Power for a major industrial hose manufacturer, with the aim of enhancing the Research & Development department and ensuring increasingly accurate tests.

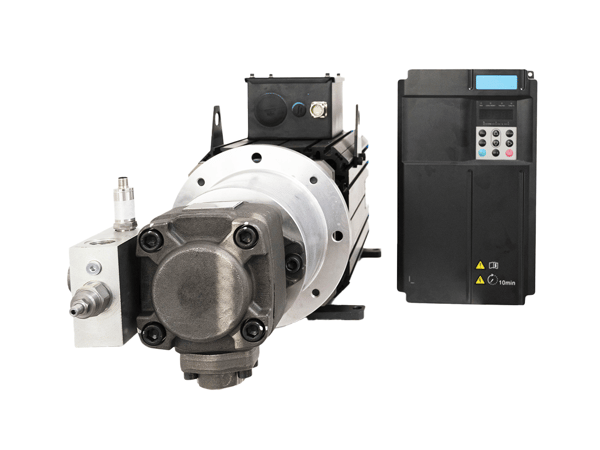

The completely custom solution integrates a Hydraut KSPH servo pump, which represents the heart of the machine's fluidic innovation: a compact, efficient, and intelligent electro-hydraulic system, designed according to the principles of Industry 5.0.

Double test chamber: impulse and burst in a single machine

One of the most distinctive aspects of the bench created by Hydro+Power is the double test chamber, which allows impulse tests and burst tests to be performed within a single machine. This versatility reduces testing times, optimizes space, and cuts operating costs, making the system ideal for those managing a high-intensity test laboratory.

- Main chamber: designed for impulse tests according to ISO 8032, EN 1664, and ISO 1402 standards. Tests can exceed millions of cycles of "revolving movement" at temperatures up to 90°C, using a water-glycol mixture as the test fluid.

- Second chamber: dedicated to burst tests, it integrates a system with a double high-definition camera to monitor hose elongation and torsion in real time during the test.

This architecture represents a benchmark in terms of safety, precision, and visual control of the tests.

An intelligent electro-hydraulic circuit by Hydraut

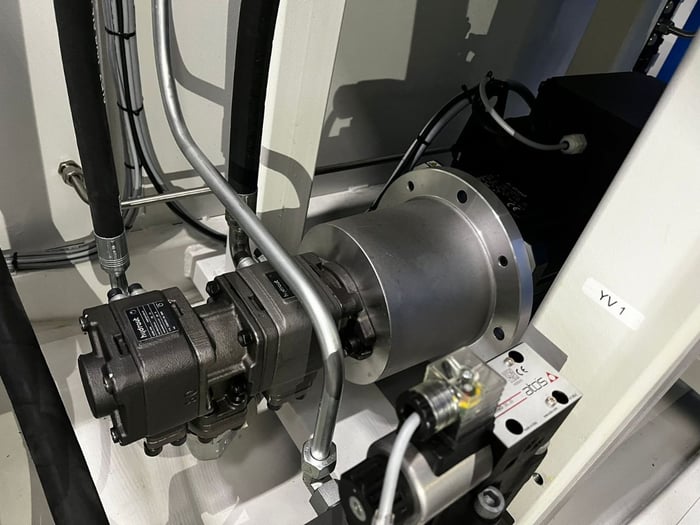

At the heart of the bench's operation is accurate plant design, centered on two key elements: a water/oil multiplier and a Hydraut KSPH servo pump unit.

Compared to traditional hydraulic circuits — based on piston pumps, accumulators, and proportional valves — the Hydraut servo pump introduces a completely new approach: it dynamically regulates pressure and flow, allowing for a drastic simplification of the circuit and a significant reduction in maintenance points.

The result is a more compact, quieter, and more reliable system, capable of guaranteeing repeatable and stable test cycles even in the presence of rapid pressure variations.

Power on demand technology and energy saving

The Hydraut KSPH servo pump adopts a power on demand operating logic:

the brushless motor and the digital inverter modulate the rotation speed in real time based on the required pressure. When the bench does not require flow, the motor stops completely, bringing energy consumption to zero.

This solution guarantees:

- significant energy savings compared to conventional systems;

- reduction of oil overheating and longer component life;

- lower noise up to 20 dB;

- electronic regulation of pressure and flow with digital precision.

Thanks to the plug & play pre-configuration and calibration carried out during the testing phase, the system arrived ready for use, simplifying installation and reducing commissioning times to a few weeks.

The solution also integrates new generation inverters that allow energy recovery logics, in line with the requirements of Industry 5.0 and the growing attention to reducing energy consumption: a high-performance, but also sustainable, test bench.

Intuitive software and advanced control

Alongside the mechanical and fluidic parts, Hydro+Power has developed dedicated management software that combines ease of use and computing power. The intuitive and customizable graphical interface allows you to:

- configure test cycles with a few steps;

- manage automatic reports and data archiving;

- connect to the company network for remote monitoring;

- perform remote assistance in case of maintenance or system updates.

In this way, the test bench fits perfectly into the paradigm of connected and intelligent industry, where hardware, software, and data analysis collaborate to improve performance.

Industrial test benches towards higher standards

The test bench developed by Hydro+Power demonstrates how collaboration with highly specialized partners and the use of systems such as the Hydraut KSPH servo pump can transform a test plant into a new generation technological platform: more efficient, quieter, more intelligent.

A concrete example of how the integration between mechanics, hydraulics, and electronics is redefining design standards in the industrial testing sector.